What You’ll Learn in This Blog:

- The structure and benefits of corrugated fiberboard.

- An overview of the different types of flutes used in corrugated packaging.

- Tips for choosing the right type of corrugated flute

- The role of corrugated materials in cost-effective packaging design and sustainable packaging solutions.

Introduction

Think about your favorite products arriving at your doorstep in an Amazon, Target, or your favorite store Box, Have you ever thought about what type of packaging used? Well many refer to these type of boxes as the “brown” or “cardboard” box. However the correct terminology is actually called Corrugated fiberboard. Corrugated fiberboard is an essential material in the packaging industry, known for its strength, durability, and versatility. Consisting of a fluted corrugated sheet and one or two flat liner boards, it is engineered to protect goods from moisture, impact, and compression. There are five main types of flutes used in corrugated boards: A, B, C, E, and F each with different dimensions and uses.

A-Flute:

- Height: 1/4 inch

- Flutes per Foot: Approximately 36 flutes per foot

- Characteristics: A-Flute provides the highest stacking strength and cushioning properties,with great shock absorption.

B-Flute:

- Height: 3/32 inch

- Flutes per Foot: Approximately 47 to 53

- Characteristics: B-Flute offers excellent crush resistance and can be used for both canned goods and displays due to its flatter surface, making it suitable for high-quality printing and die-cutting.

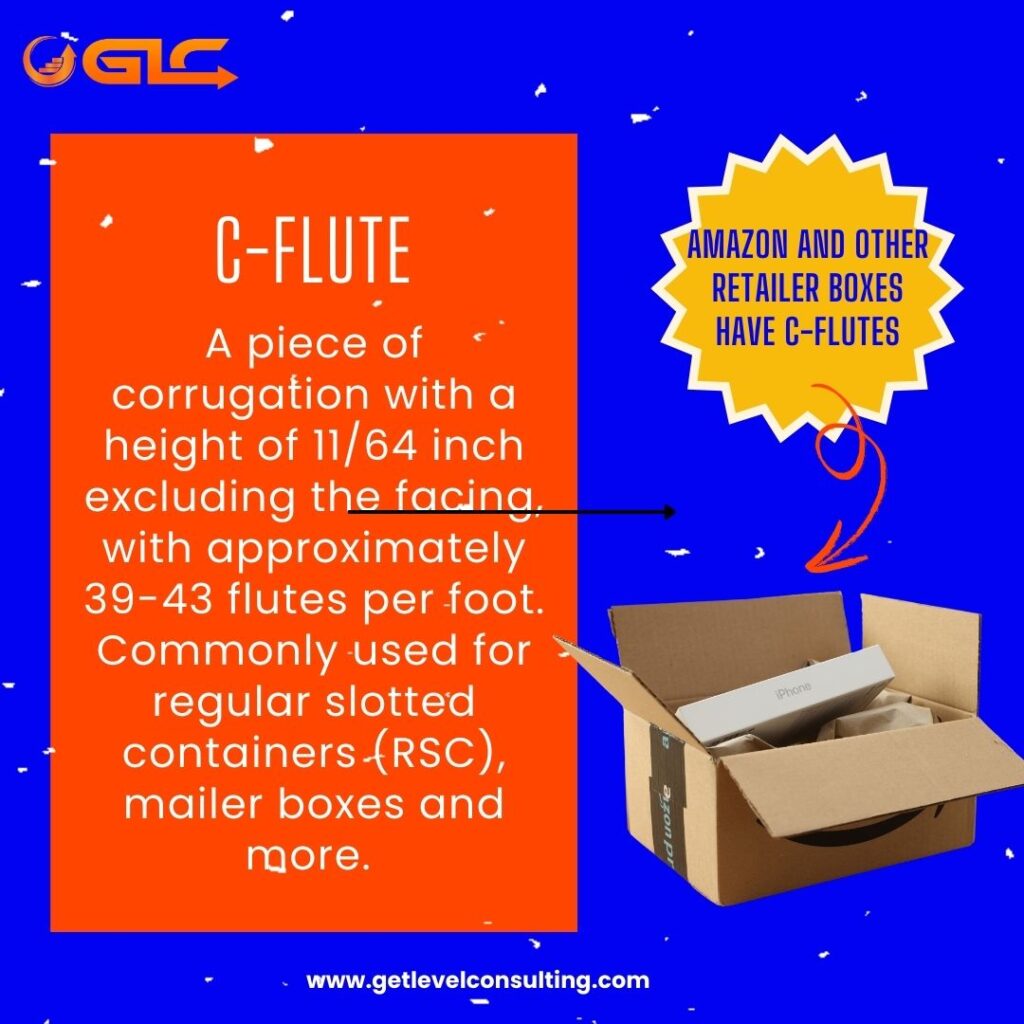

C-Flute:

- Height: 11/64 inch

- Flutes per Foot: Approximately 39-43 flutes per foot

- Characteristics: C-Flute has a good stacking strength and crushing resistance, This Flute is the go-to for standard box styles, like regular slotted containers (RSC), which is the Amazon box delivered to your doorstep.

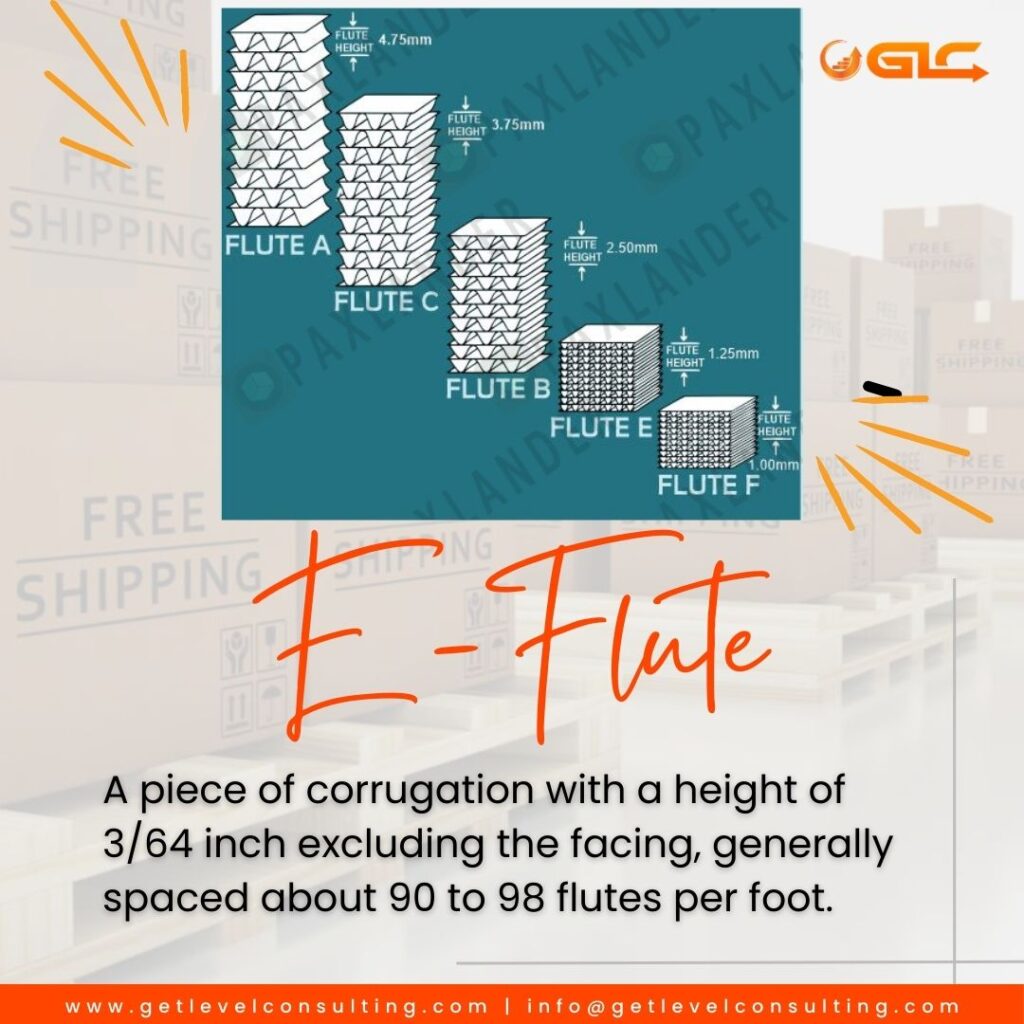

E-Flute:

- Height: 1/16 inch

- Flutes per Foot: Approximately 90-98 flutes per foot

- Characteristics: E-Flute has a very flat surface and higher flute count which provides an excellent surface for printing. It is typically used for smaller boxes and retail packaging. THese are commonly seen in serum skincare boxes, cosmetics and similar.

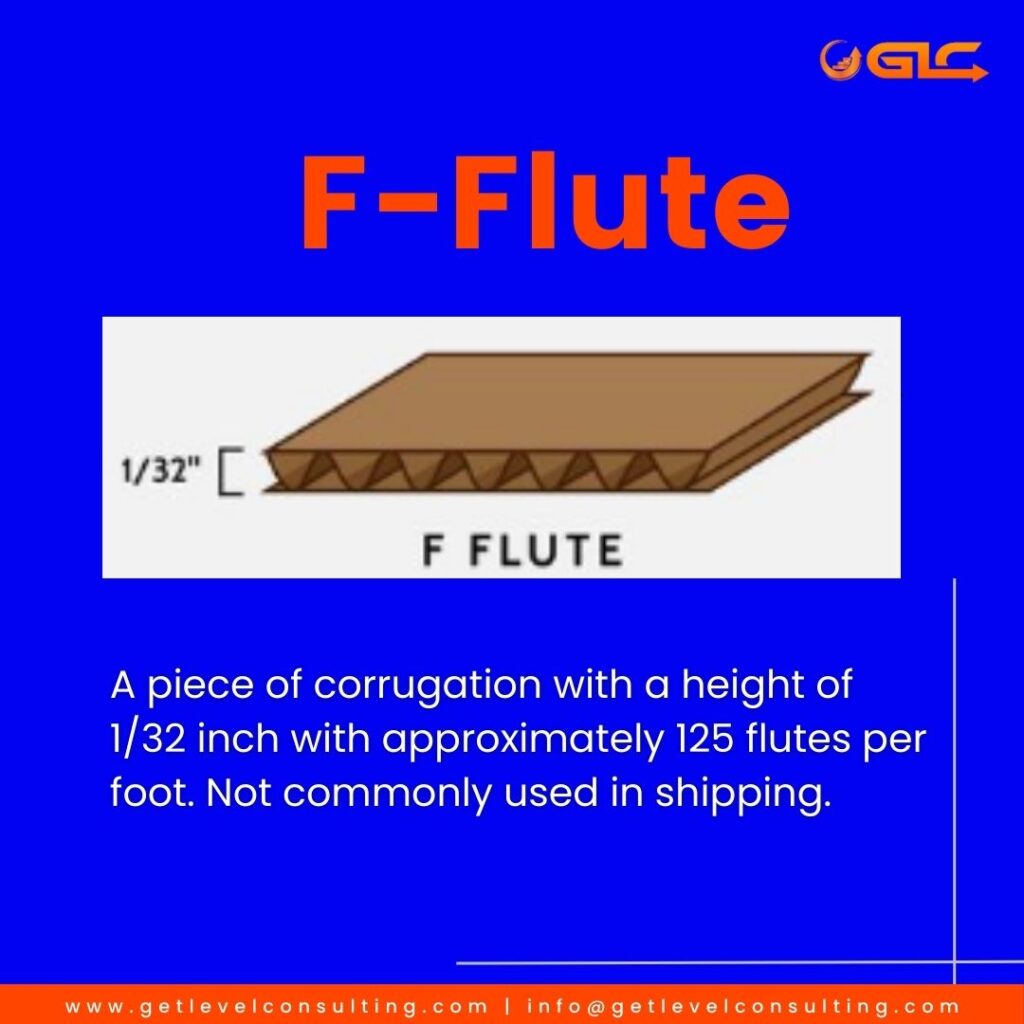

F-Flute:

- Height: 1/32 inch

- Flutes per Foot: 125 flutes per foot

- Characteristics: F-Flute is the thinnest flute style and has a very flat surface and higher flute count which provides an excellent surface for printing. It is typically used for smaller boxes and retail packaging.

Selecting the Right Type of Flute

Choosing the right flute type depends on the requirements of the packaged product, including protection level, box strength, stacking capability, and whether the packaging will be used for retail display. For instance, A-Flute is preferable when high cushioning and thickness are needed, whereas E-Flute suits applications where a smooth surface for printing and an aesthetically pleasing appearance are more critical. Protection is key when selecting the right type of flute and corrugated fiberboard. Check out our clip on 4 Functions of Product Packaging: Protection.

Sustainability and Cost-Effectiveness

Corrugated fiberboard is recognized for its sustainable packaging solutions. Made from renewable resources and highly recyclable, it plays a significant role in the circular economy. The material’s lightweight nature contributes to cost-effective packaging design by reducing shipping costs and the environmental impact associated with transport.

Additionally, the adaptability of corrugated fiberboard to various flute types allows manufacturers to customize the packaging based on specific needs, effectively balancing protection, cost, and sustainability. As packaging trends 2025 evolve, the focus is increasingly shifting towards optimizing packaging designs that meet both functional and environmental standards.

Corrugated fiberboard and its diverse flute options demonstrate the industry’s capability to innovate continually, providing robust solutions that safeguard products while supporting global sustainability efforts. By choosing the right type of flute for their products, businesses can enhance packaging performance and contribute to broader environmental goals.

Stay Updated with the Latest in Packaging Solutions!

Keep ahead in the packaging industry by following our latest updates on social media (Linkedin, Instagram). Subscribe to our biweekly newsletter here for the newest insights and strategies directly in your inbox. Explore more detailed articles on our website here, and tune into our Product and Packaging Powerhouse™ Podcast, where we talk about industry trends and innovative solutions.

Connect with us today and enhance your packaging knowledge.

Megan Young Gamble, PMP® is a forward-thinking packaging and project management veteran with more than 10 years’ of experience transforming mere ideas into consumer product goods for today’s leading beauty, wellness, and personal care brands. Known amongst colleagues and clients for her perseverance and “see it through” mentality, Megan The Project ExecutionHER® is the owner and principal consultant of GLC, packaging & project execution team for CPG brands, Co-Owner of Pallet Pros, and Host of Product & Packaging Powerhouse Podcast.

- [FREEBIE] Learn about “day in the life” of a Packaging Project Manager → Get our “Starter Packaging PM Freebie” [link] https://glc.ck.page/thestarterpackagingprojectmanager

- Subscribe & Access our Video Vault YouTube Channel [ link] https://bit.ly/GLConYouTube

- Join our Email List [link] https://glc.ck.page/55128ae04b

- Follow and Connect with Megan on LinkedIn [link] https://linkedin.com/in/megangamble

- Learn about GLC, Packaging & Project execution firm for CPG brands http://www.getlevelconsulting.com

- Work with Me @ GLC, Schedule Discovery Call https://calendly.com/getlevelconsulting/15-minute-insight-session